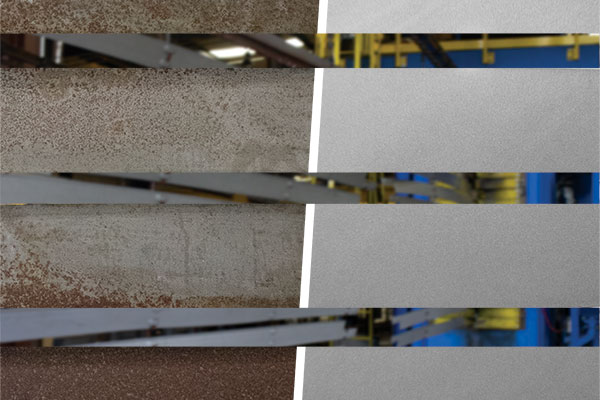

is an all-too-common occurrence on steel edging. It is aesthetically displeasing and affects the integrity of your landscape installations. Conventional methods of pre-washing and powder coating the steel does little to eliminate rust and scale. These and other contaminants prevent paint finish from adhering properly resulting in delamination and rusting.

The JD Russell Company is the only landscape edging manufacturer to use the Blastec system to bring steel to near white metal condition in compliance with SSPC 10/ NANCE and SSPC 5.1.4. powder coating standards.

As a staple in the industry, powder coating has proven to be one of the most popular paint applications for steel landscape edging. What powder coating does well is extend the life of the metal that has been coated.

When the coating is cured it develops into a durable and hard finish. This extra layer of protection helps protect against corrosion, heat, wear-and-tear, weather, and everyday scratches. Although it looks like a common 2-coat paint application, powder coating provides a beautiful layer of protection that is unrivaled by liquid paint.

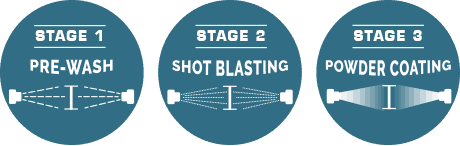

After the raw steel is made into punched edging, it’s treated with a detergent pre-wash. This wash removes oils, grease and hard to see contaminates from handling and readies the steel for stage 2 – Shot Blasting.

Shot blasting is a mechanical method of propelling abrasive material using a centrifugal wheel to remove surface contamination, scale and other impurities from steel prior to powder coating. The J D Russell Company is the first and only landscape edging manufacturer in the nation to use the Blastec shot blast system prior to powder coating.

After being completely cleaned and shot blasted, the edging is coated with a high quality TGIC durable powder coating that is compliant to ASTM standards. It is then baked to a highly durable finish. This coating protects the steel from rust and corrosion caused by humidity, salt spray or sunlight insuring longevity and a high end look for many years to come.

Blasted and ready for powder coating.

SSPC 5.1.4 Blast Cleaning – For the removal of all dirt, grease, rust scale, foreign material and mill scale, rust, old paint and slag to the extent that staining is limited to light shadows , slight streaks, or minor discolorations caused by stains of rust, stains of mill scale, or stains of previously applied paint. Bare steel surfaces have a layer of iron oxide that must be removed before powder coating will adhere to the bare steel. Blast cleaning shall be performed in accordance with SSPC Surface Preparation Specification 6. After blasting operations are completed, all surfaces shall be cleaned of blasting products and other residue by the use of compressed air or vacuumed.