What Is Shot Blast Edging?

Steel landscape edging helps define and retain your landscaping, which is important if you want to create a meticulous design that holds up over time. Unfortunately steel edging is susceptible to some drawbacks, but shot blast edging provides a convenient solution with its three step process. Read on and learn what you need to know about shot blast edging.

Edging Problems

People use landscape edging to make their landscaping more visually appealing. It changes the makeup of the yard by separating it into different sections, which make it more interesting to look at. The bad news is that steel landscape edging is prone to several issues, and rust and paint delamination are particularly problematic. The rust and scale that builds up on your landscape edging will be an eyesore, and it can also affect the structural integrity of the edging itself.

Three Step Process

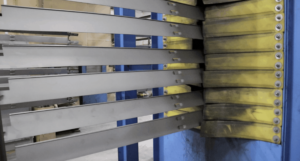

In just three steps, shot blast steel surface preparation can create the ideal steel landscape edging. Shot blasting removes rust and scale from the edging material, and it also smooths out any other impurities. Then, an acid coat is applied to the steel to make the third stage, powder coating, more successful. In the last stage the steel is powder coated to prevent problems like rust, scale, and peeling. This leaves you with pure steel landscape edging materials that will last longer and look better.

Aesthetic and Functional Solution

Shot blast edging makes your steel landscape edging look better, which directly translates to the look of your property. It also helps the edging last longer, since it’s not as vulnerable to the corrosive effects of rust and scale.

Are you looking for tools to use for an upcoming landscaping or construction project? Call JD Russell at: (800) 888-7425. We sell both landscaping and construction materials that are made right here in America. Visit our website for more information.